New model helps to develop foods with customizable digestive qualities

Digestion is the process that allows the body breaks down a cheeseburger into nutrients that the cells in your body can use. With the help of new technology at UC Davis, this process can now be examined outside of the body.

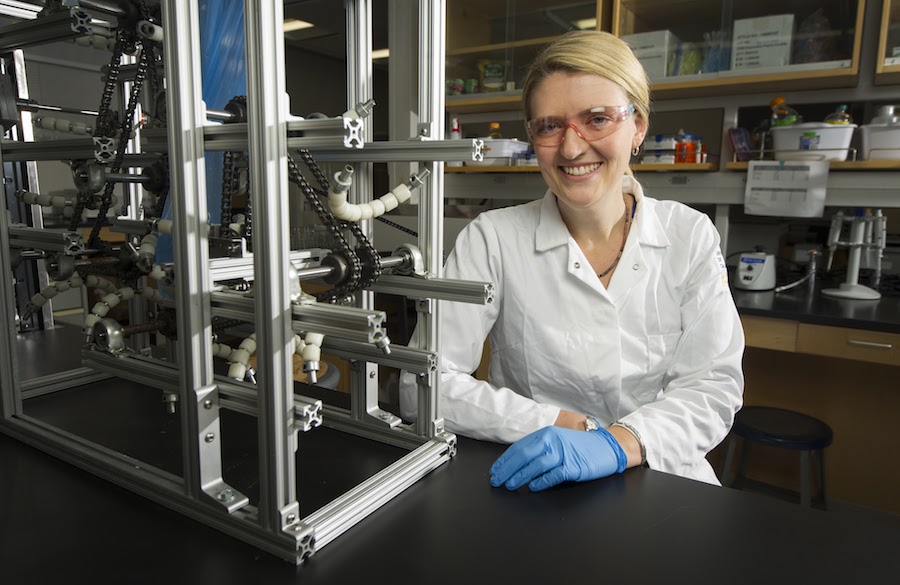

Gail Bornhorst, an assistant professor of food science and technology, was on the team that first built the human gastric simulator (HGS), a model that simulates human digestion.

“Our main goal was to be able to simulate both the the physical and the chemical aspects of food digestion in order to understand food breakdown processes to be able to model those processes, ultimately [designing] better food products that have the functional properties that we want,” Bornhorst said.

The HGS is unique because it models both chemical and physical digestion, two independently complicated processes.

“The physical aspect is that [the HGS] essentially has these rollers that move down a stomach reactor, and those mimic the contractions of your stomach,” Bornhorst said. “Your stomach has muscular contractions and that’s how it breaks down the food particles.”

While chewing starts the process of physical digestion, it still leaves food particles largely intact, so as the rollers are moving along the stomach reactor, the process of chemical digestion is also happening.

Yamile Mennah-Govela, a Ph.D. student of food science and technology, also works in Bornhorst’s lab. Components for chemical digestion are made in the lab using a unique blend of enzymes, salts and glycoproteins that simulate saliva, gastric juice and internal fluids, according to Mennah-Govela.

“We make it as solution, and we make a bottle of it,” Mennah-Govela said. “We store it in the refrigerator and we can use it within one week for different trials.”

Although the process of modelling digestion may sound simple, the enzymes that your body produces, as well as other factors, can vary drastically.

“We do sequential digestion, where we would mimic the stomach and then mimic the small intestines,” Bornhorst said. “The challenging part about that is that there are a lot of control systems: how fast [food] empties from your stomach, the secretion of acids and enzymes, and a lot of those are dependent on the food product and they’re also dependent on the individual […] There’s some data that exists from human studies, but if you’re using a different food product, then the values may be very different.”

If digestion is so hard to recreate, it might seem counterintuitive to try to mimic the process outside of the human body. Karen Rios-Villa, a graduate student in the Food Science Department, also works in Bornhorst’s lab. According to Rios-Villa, there are a couple of reasons why the development of the HGS was necessary.

“Most of the research regarding nutrient release is related to the after-absorption process, but the transformation that the food suffers during digestion is still not clear,” Rios-Villa said in an e-mail interview. “A possible way to understand this process would be using animals (“in vivo”), but there are numerous ethical, economical and methodological limitations. Therefore, the development of tools that can help us in the simulation of digestion have been built in Prof. Gail Bornhorst Food Engineering Lab.”

One of the ways the HGS is being used is to study how different ways of preparing food can change the breakdown of proteins and overall bioavailability, or the percentage of each nutrient that your body is able to absorb, of the nutrients that food contains.

For example, Bornhorst’s group did some work with sweet potatoes, preparing them in various ways, feeding them through the machine and then analyzing the broken down food. In the future, Bornhorst sees a place for models like the HGS in trying to engineer foods with specific desired properties, like a food that will make people feel fuller, or have a slower or faster release of glucose.

“All those things are related to the properties of food products and what actually happens to them when you eat the food,” Bornhorst said. “Because the models that we’ve had in the past did not incorporate both the physical aspects and the chemical aspects, we were trying to optimize a system where we didn’t really understand what was going on. By creating these types of models, like our mechanical stomach model, what we’re really trying to do is to be able to understand, at a much more detailed level, what’s happening both to the structure as well as to the properties after you consume the food”.

Written by: Meral Basit — science@theaggie.org